The automotive industry has always been at the forefront of embracing advanced technologies to meet ever-growing demands for precision, speed, and cost-effectiveness. One such technology, the integration of CAD/CAM systems in prototype automotive components machining, plays a pivotal role in enhancing machining accuracy. JUPAICNC, a leader in precision machining, has continually embraced cutting-edge tools to ensure that the components produced meet the highest standards of quality and performance. Through the application of CAD/CAM in automotive prototype machining, manufacturers can achieve unparalleled accuracy, streamline production processes, and bring prototypes to life with exacting detail. These systems allow engineers to translate their design ideas into tangible prototypes with a high degree of precision, ensuring that every component produced aligns perfectly with specifications. This advancement, driven by JUPAICNC’s expertise in automotive components machining, significantly impacts both the production time and the cost efficiency of manufacturing prototypes.

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems are integral tools in modern machining processes, particularly in the automotive sector. When it comes to prototyping, these technologies provide immense benefits that go far beyond simple design creation. CAD enables designers to create highly detailed 3D models of automotive components, while CAM converts these models into instructions that guide the machining process. The precision of these instructions directly affects the quality of the final product, ensuring that prototype automotive components are manufactured with exact accuracy. By using these technologies in conjunction with advanced CNC (Computer Numerical Control) machines, manufacturers like JUPAICNC can consistently produce prototypes that meet stringent design requirements and quality standards.

The use of CAD/CAM systems in automotive components machining allows for the precise simulation of manufacturing processes before the physical machining takes place. This is a critical step in identifying potential issues, such as design flaws or manufacturing inefficiencies, that might otherwise go unnoticed until production begins. With the ability to virtually prototype a component, manufacturers can make adjustments to the design early in the process, reducing the need for costly revisions and rework down the line. Moreover, CAD/CAM software can simulate various machining strategies, allowing engineers to select the most efficient approach for each specific component, thus optimizing both accuracy and material usage during the production phase. For companies like JUPAICNC, this capability ensures that every prototype is not only accurate but also optimized for performance.

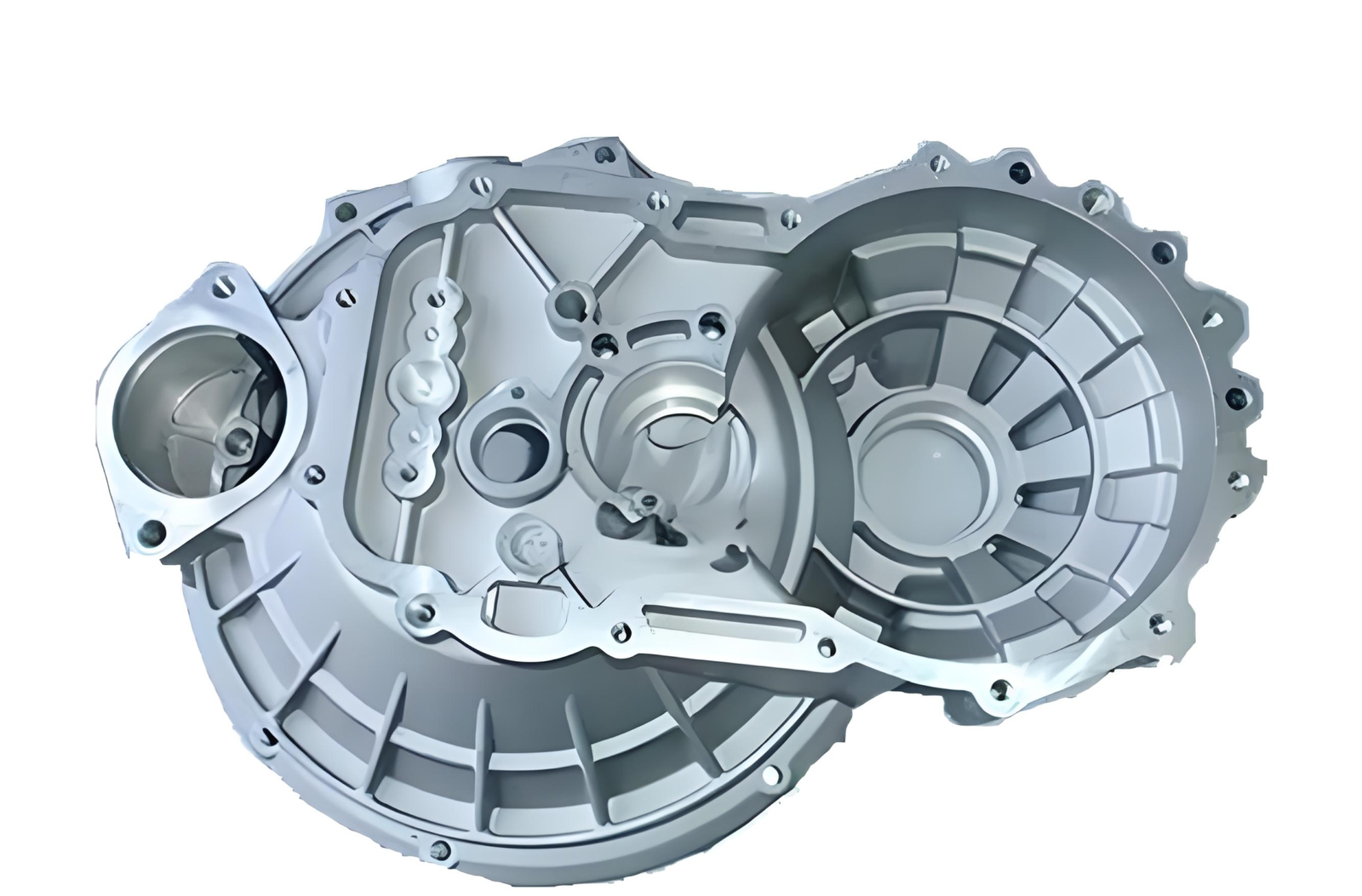

Furthermore, the integration of CAD/CAM systems in automotive components machining enhances the ability to work with complex geometries and intricate designs. Traditional manufacturing methods often struggle with producing such components with high accuracy due to the limitations of manual techniques or older CNC machines. However, with modern CAD/CAM systems, designs that incorporate highly complex shapes, fine details, and tight tolerances can be created and machined with precision that was previously unattainable. This level of complexity is especially important in automotive prototyping, where even the smallest deviations from the design can lead to poor performance or failure during testing. By utilizing CAD/CAM technologies, JUPAICNC ensures that every prototype, no matter how complex, is machined with the utmost accuracy.

In addition to enhancing the accuracy of machining, CAD/CAM systems also contribute to faster turnaround times in automotive prototyping. Because CAD models are directly converted into machine instructions, the need for manual programming is eliminated, drastically reducing the time spent on setup. Additionally, the ability to simulate and optimize machining processes before actual production starts leads to smoother workflows and reduced downtime. This efficiency is critical in the automotive industry, where time-to-market is often a key factor in gaining a competitive edge. JUPAICNC has leveraged this advantage, allowing clients to receive their automotive prototypes more quickly without sacrificing quality or precision.

Another significant advantage of CAD/CAM integration in prototype automotive components machining is its ability to maintain consistency across multiple parts and production runs. Once a CAD model is created and the CAM system is programmed, the same process can be replicated indefinitely, ensuring that each prototype component produced is identical to the previous one. This repeatability is essential in automotive manufacturing, where even small variations between components can lead to issues in assembly or performance. The precision enabled by CAD/CAM systems ensures that every component produced meets the required specifications, eliminating the risk of errors that might arise from human intervention or inconsistent manual processes. This reliability is one of the key reasons why companies like JUPAICNC continue to rely on CAD/CAM for their prototype automotive components machining needs.

Moreover, the continuous development of CAD/CAM technology has led to further enhancements in machining accuracy. As these systems evolve, they integrate new features such as advanced toolpath generation, real-time monitoring, and adaptive machining strategies. These innovations allow for even greater precision in the machining of complex automotive components. For example, advanced toolpath algorithms can optimize cutting strategies to reduce tool wear, improve surface finish quality, and enhance the overall lifespan of the machinery. These improvements contribute to the precision of the final prototype while also reducing production costs over time.

By incorporating CAD/CAM systems into their automotive components machining processes, companies like JUPAICNC are able to achieve a level of precision and efficiency that would be impossible with traditional methods. These systems not only enhance the accuracy of each individual prototype but also contribute to overall improvements in production workflows, cost management, and time-to-market. The ability to create and machine prototypes with such high precision is invaluable in the competitive automotive industry, where innovation and performance are paramount. As the automotive sector continues to evolve, the role of CAD/CAM systems in automotive components machining will only become more integral, helping manufacturers meet the increasing demands for precision, efficiency, and quality.